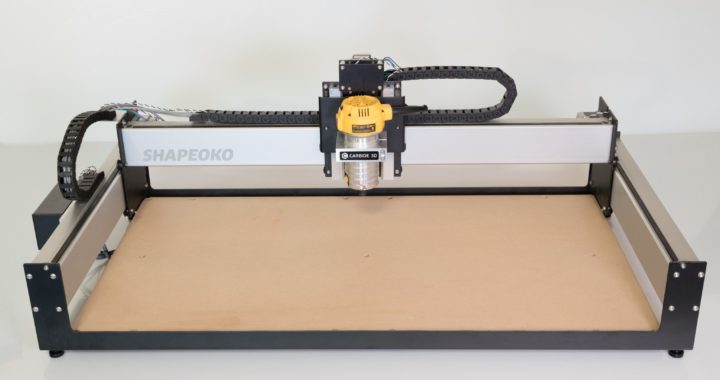

Overview

A small but powerful CNC router. A CNC router takes a large piece of stock material and carves out a part. The machine instructions for a CNC are called g-code and can be generated from a CAD file.

Capabilities

Cutting Area

The Shapeoko has a cutting area of 16 in by 33 in

Horse Power

The Shapeoko has a maximum horse power of 1.25 HP

Collet Size

The collet size of the Shapeoko is 0.25 in

Materials

Softwoods, hardwoods, plastics, and foam can all be machined on the Shapeoko. For a comprehensive discussion of materials on the Shapeoko, see the Shapeoko wiki page on materials. Note, due to spark hazard, metals cannot be machined in the Invention Studio wood room.

PPE

Required: Safety glasses, closed toed shoes, no loose or dangling items on person (hair tied back; no necklaces, hoodie strings, ect.)

Recommended: Hearing protection, respirator

Safety Features

In the event of unexpected behavior that does not pose an immediate threat to the machine or workpiece, pause the job in Carbide Make. If an immediate threat is presented, turn the machine off using the same switch used to turn it on. This will not turn off the router. After the Shapeoko is off, turn the router off if it is possible to reach the button safely.

Maintaining safety on the Shapeoko comes down to three things, staying away from the path of the router, good hold down/ fixturing, and good speeds and feeds. Make sure that there are no loose objects in the path of the router, and never reach into the Shapeoko bed when the router is in motion. If stock is not secured to the spoilerboard, it can be thrown when contacted by the router. When using untested speeds and feeds, always be conservative to avoid breaking tools or throwing parts.

Example Work

Topographical State

After working with softwoods, the world of CNC routing opens up. Hardwoods and engineering plastics are capable of holding tight tolerances and more detailed features than foam or softwood. This tutorial on making a topographic map of a state is a good introduction to more complex projects, and the Fusion 360 CAM workspace.

How To Use This Tool

- Turn the Shapeoko on with the power switch

- Using Carbide Make, home the machine, then load a GCode file (see [Carbide Make])

- Secure stock to the spoilboard

- When not doing through cuts, use the screw clamps and guide pieces to hold the stock in place

- When doing through cuts, or when the stock is too small to secure with clamps, hot glue the stock to a larger sacrificial piece and then clamp that piece in

- Zero each axis in accordance to the origin of the GCode file to be run (see Carbide Make article)

- Use the wrench to loosen the collet on the Dewalt router

- Insert the tool needed for the job to be run into the collet, then tighten

- Turn on the router

- Set router speed using the dial on the top of the router. For speed settings, see the link in the materials section

- Run the GCode through Carbide Make

- Turn off the router

- Vacuum the chips and dust produced by running the router

- Remove tooling from the collet and return it to its container

- Put away the fixturing used for the job

Homing Error

Sometimes the Shapeoko will fail to properly home. When this happens, turn off the Shapeoko and manually move the router away from the back left corner. Restart [Carbide Make], then power on the Shapeoko and try again.

Charring or Melting

- Surface charring in woods or melting in plastics may occur when heat buildup is not under control. Higher chip load allows for greater cooling. In practice, this means dialing down the speed or raising the feed will reduce charring and melting.

Deflection

- Too high of a step down or feed rate can cause the tool to bend. This deflection is dangerous and can lead to tool breakage at worst, and poor dimensional accuracy of a job at best.

Multiple Tool Jobs

- To run a job with multiple tools, simply swap bits and zero Z again between each GCode file. See the multiple tool jobs section of the Carbide Create article for more information.

References:

Coaster Project. (n.d.). Retrieved from http://docs.carbide3d.com/tutorials/project-coaster/

(2018, February 12). CNC Topographical Wooden State. Retrieved from http://www.instructables.com/id/CNC-Topographical-Wooden-State/

Materials. (2018, June 18). Retrieved from https://www.shapeoko.com/wiki/index.php/Materials

Shapeoko 3 - Hello World. (n.d.). Retrieved from http://docs.carbide3d.com/tutorials/hello-world/

Author Information

Article was written by Michael Burton, and edited by Reed Morris

Last Updated: September 6 2018.