How to Print

If you want to get something resin 3D printed at the Invention Studio, there is an easy 4 step process to create your parts! Like our standard 3D printing, resin printing, including the resin, is completely free.

This page will guide you through the process of generating your STL, slicing your part, cleaning your part, and curing your part, but it does not replace formal resin training and testing. You may not touch anything within the resin printing area without having completed the training and test. Thankfully for you, we train all of our full Prototyping Instructors on how to safely operate the resin printers and related post-processing, so you can still get parts without undergoing training and testing yourself.

Resin Print with ENGINEERING RESINS: Ticket Submission Link

1. Generating Your STL

There are countless proprietary file encoding systems to store information about a three dimensional object, but thankfully there is a universal standard that all 3D printing workflows use as their starting point: the STL.

STLs consist of many triangular faces which approximate the outside surface of your 3D part.

If you are getting your design from some online repository of files, like Thingiverse, the files will almost certainly be delivered in STL format.

If you are designing the part yourself in Solidworks, Fusion 360, or any other CAD software, the STL file format will be available in some export or save-as menu. Make sure to check your settings when exporting to an STL. Solidworks, for example, defaults to 10 degree angular resolution, so a circle is approximated to 36 faces, which is not much when creating a wheel! Be careful with too fine of an STL though, as the slicing times scale with the number of faces in the part.

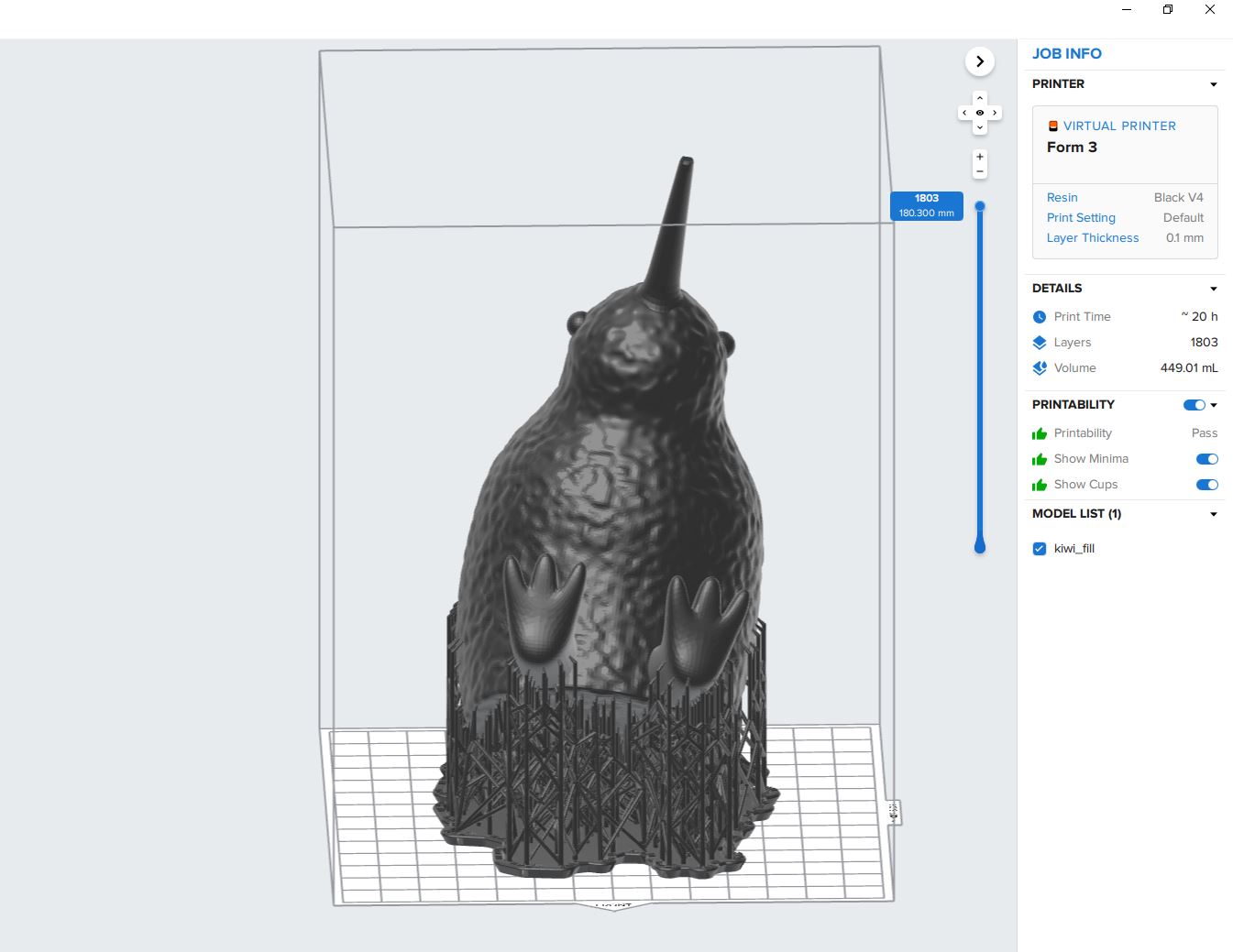

2. Slicing Your Part

In a broad sense, slicing is the process of turning your generic STL file into machine instructions that the 3D Printer can understand.

Resin 3D printers operate by extruding material in a 2D layer, and then shifting that layer downwards and building another layer on top of it.

These discrete layers come together to make a complete 3D shape. Slicing turns your 3D STL model into a set of 2D "slices" that the printer can actually produce.

Since all of our printers are Formlabs, we use PreForm, their slicing program. It is free to download on your machine, and we have it set up on our computers at the Studio.

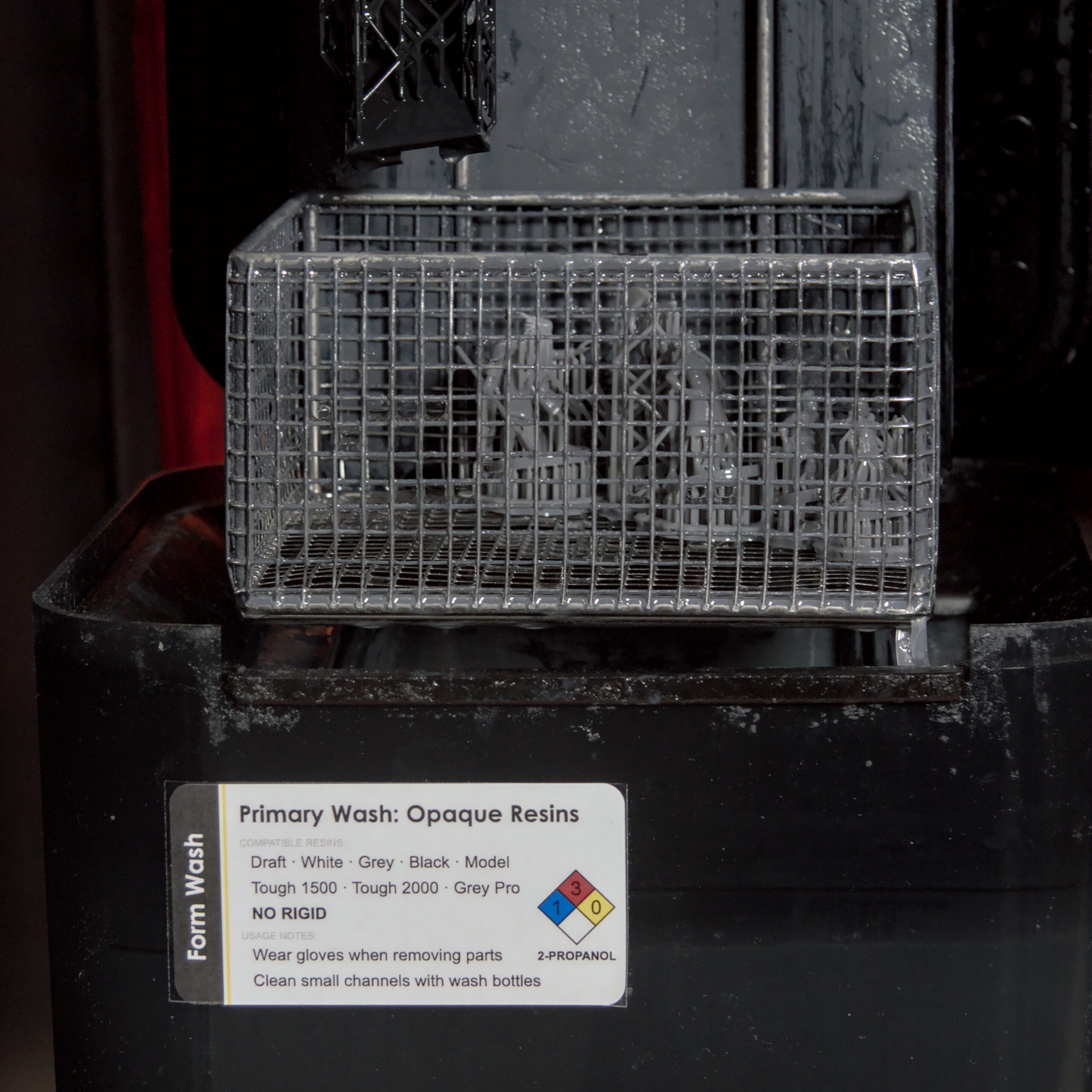

3. Cleaning Your Part

Liquid resin is nasty stuff, so we need to clean it off completely before touching the parts with our bare hands.

Our cleaning process consists of using these specialized tanks, called Form Washes, which are filled with Isopropyl Alcohol. The Isopropyl Alcohol will dissolve the liquid resin that is remaining on your part without damaging the parts that the laser in the printer has already hardened.

Once you put your parts through the Form Wash, you should inspect them for remaining liquid resin and then leave them to completely dry before curing. If any liquid resin is still present inside of small features, use the hand bottles present in the cleaning area.

Every Form Wash has a different purpose, so make sure to quickly check yourself on the label before putting parts into it!

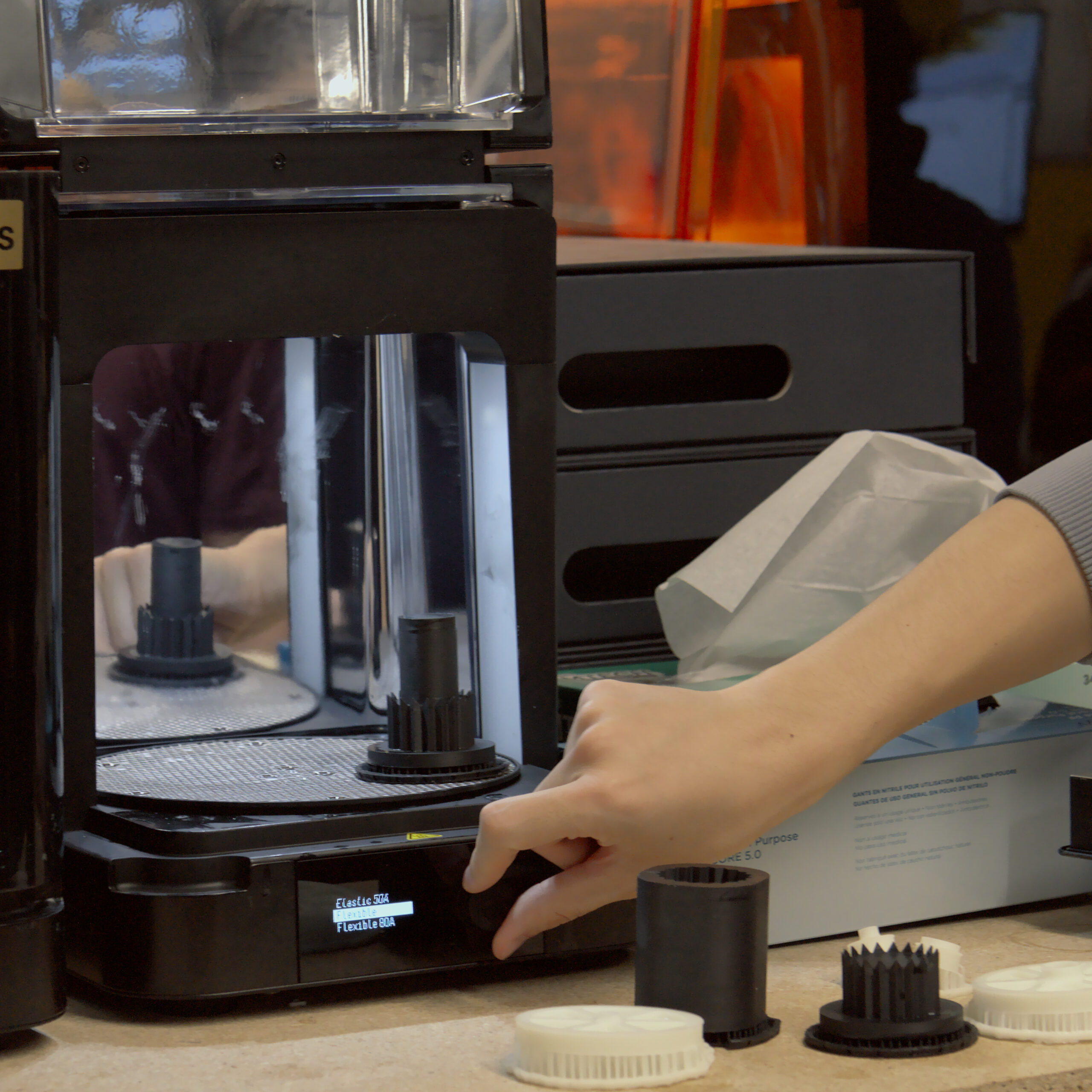

4. Curing Your Part

At this point your part is completely dry, and all liquid resin has been cleaned off, so it is safe to hold in your bare hands.

Unlike PLA prints that you may have done before, resin prints are not at their peak strength when they come off the printer. In fact, they are only at around 60% of their maximum strength.

You can look through the exact numbers according to Formlabs, the resin manufacturer. If you're not an aspiring mechanical engineer though, the key idea is that curing your parts makes them a lot stronger, at the expense of making them more brittle.

This isn't always the best choice for every project, but we recommend curing parts unless you have a reason not to.

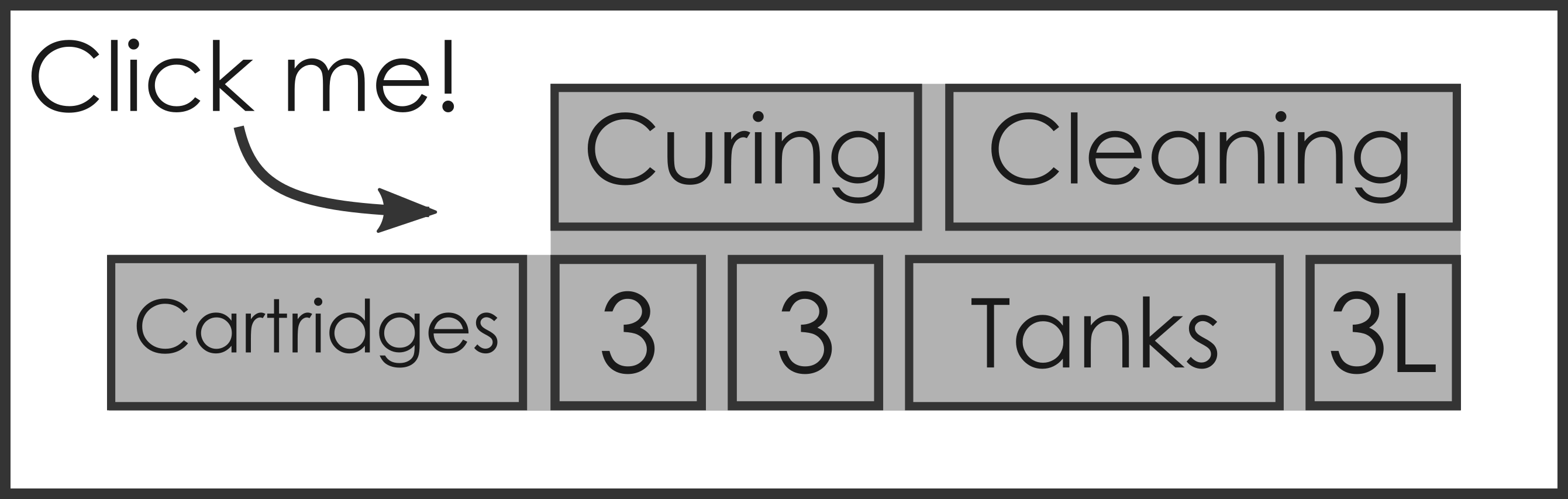

3D Printer (Resin) Map

Here is a graphical overview of Resin setup! Click on each box to learn more.

Cartridges

We have a wide selection of resins available for your use, each with its own best use case! Each cartridge matches with a corresponding tank.

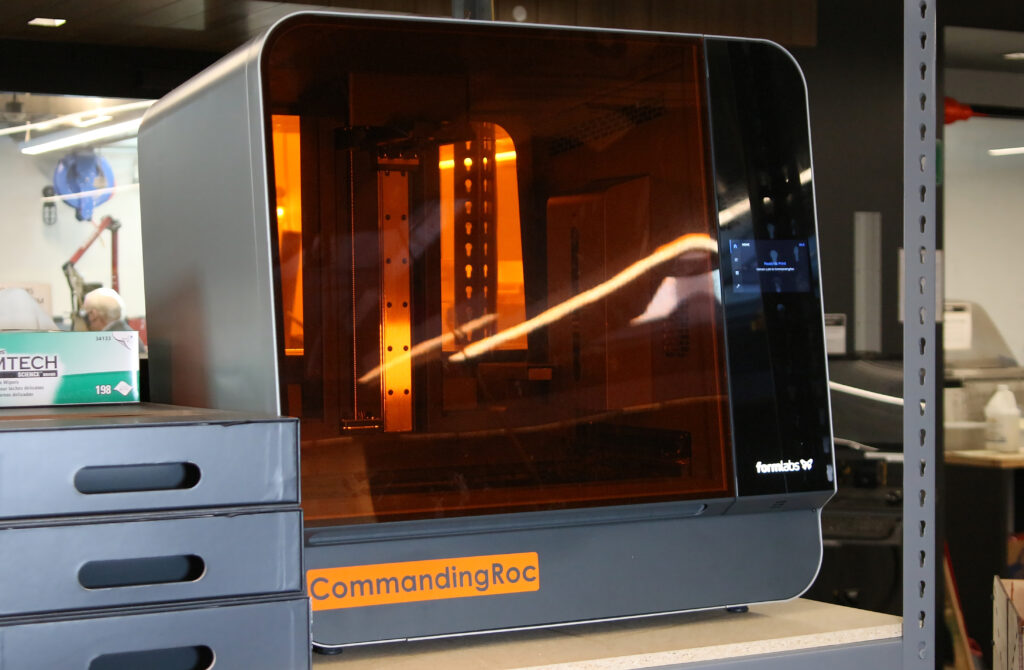

Formlabs Form 3

Our standard form factor SLA printer. Used for most jobs, and if you have a particularly large print, check out the Formlabs Form 3L!

Resin Tanks

We have a wide selection of resins available for your use, each with its own best use case! Each task matches with a corresponding cartridge. Our 3D Printer masters have created stickers on the tanks with mechanical properties to make it even easier to select the right resin for the job.

Formlabs Form 3L

Our large form factor SLA printer. It even has space to hold two cartridges so that your print will not run of resin!

Curing Stations

These stations allow your part to be cured so that it can achieve optimal material properties.

Cleaning Stations

These stations clean off the remaining liquid resin from your parts so they are safe to handle.